The Oil Sands Opportunity

Tar-sands, also known as oil sands, are sands that are saturated with bitumen, which is a highly viscous form of oil.

Extraction of oil from oil sands already represents a large-scale commercial undertaking globally, especially in the Athabasca region of Alberta, Canada.

Places such as Canada where the Canadian oil sands are located are water wet, whereas the Utah oil sands, where Greenfield is located are oil wet, therefore our process is much cleaner, uses no water and no emissions.

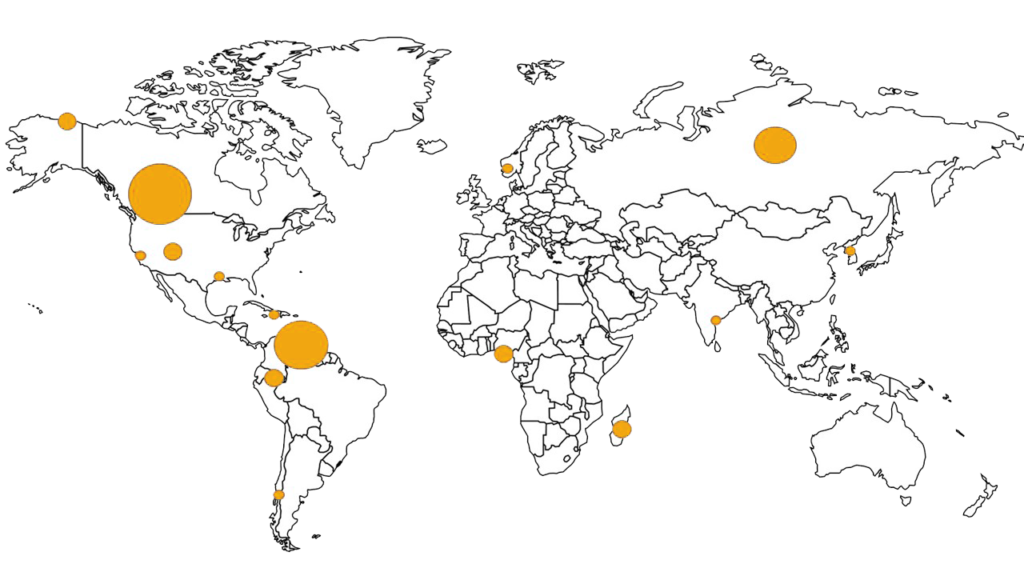

The following map shows major known oil sands deposits in the world, with the size of dot being illustrative of the relative size of the resource

Major Global Oil Sands Resources

Source: Proactive Research

The dot in the middle of the USA represents the Green River formation, which includes the Uinta basin.

The following UGS table summarises the biggest oil sands deposits identified in the Uinta Basin:

The following UGS map shows the location of these oil sands deposits within the Uinta basin: